Maximizing heavy oil recovery with custom-engineered solutions for efficient, safe, and cost-effective Cyclic Steam Stimulation (CSS).

The Great North Cyclic Steam Stimulation (CSS), or “Huff-and-Puff,” runs in cycles of steam injection, soak, and oil production. Steam is injected into a well at 300-340°C (572-644°F) for weeks, sometimes up to months. The well then sits for a period of time to allow the heat to be soaked into the formation. Then, the hot oil is pumped out of the well. Once the production rate falls, the well is run through another cycle of steam, soak, and production.

Features

- Engineered to order designs

- Cost saving solutions driven from our experience

- On-time delivery, leveraging our in-house machine shop when required

- Safety stock and semi-finished components

- Interchangeability of equipment to support existing fields

Engineered for Excellence. Our Injector and Producer, Well Pair, delivers proven performance, tailored solutions, and unparalleled reliability to optimize your thermal operations.

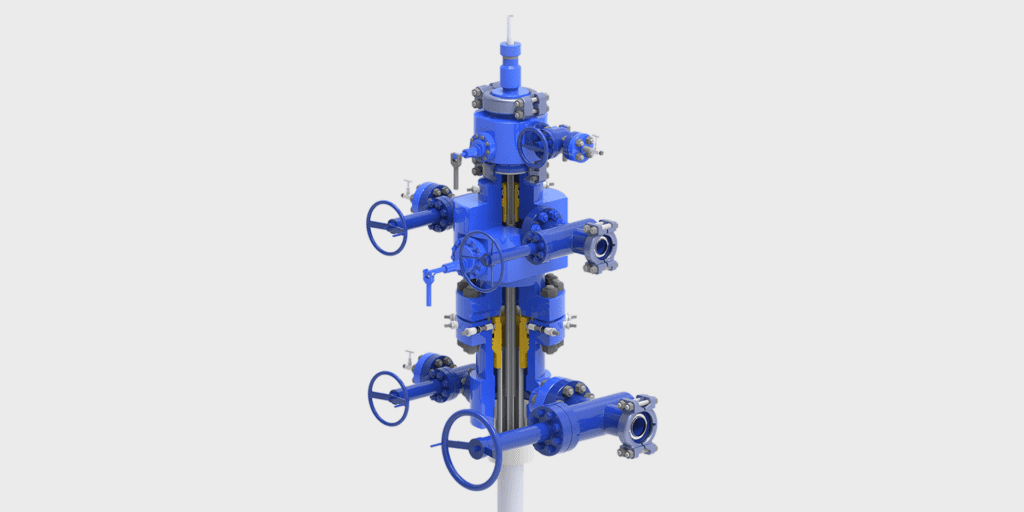

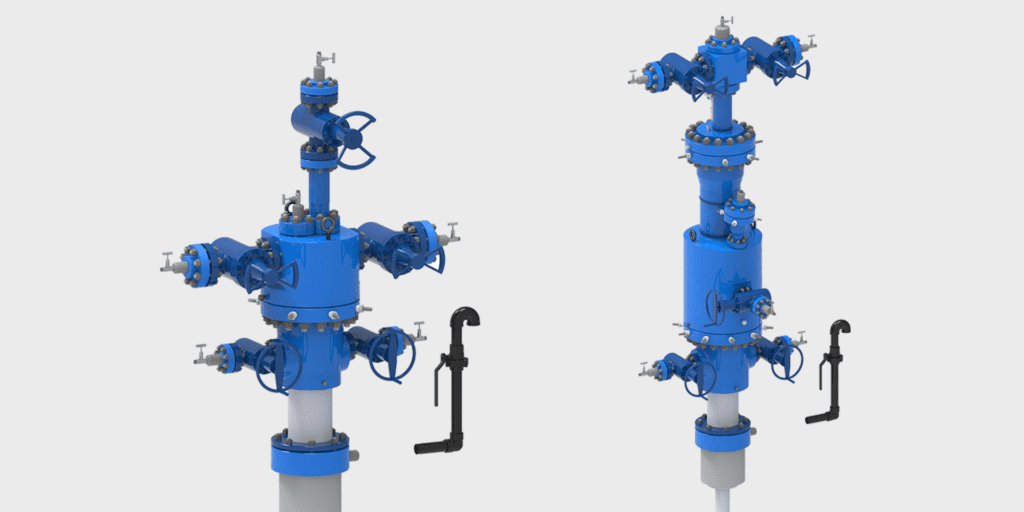

Incorporating a deep understanding of operator needs, meet Great North’s Injector and Production Wellhead (as shown left to right). Bespoke thermal wellhead design tailored for all temperature requirements, often reaching up to 650°F (343°C). Our wellheads incorporate specialized ports for electrical feed-through cables and instrumentation, allowing seamless integration within modern production facilities. Alternate configurations are available, the Circulation Wellhead being one of the producer configurations.

Features

- Tailored for all temperatures, reaching up to 650°F or 343°C

- Backed by an extensive track record in steam-assisted oil sands production in Canada

- Suitable for both power generation and district heating applications

- High-temperature valves and seals rates to 650°F

- Large diameter through-bores available for high flow rates

- Facilities instrumentation such as Electric Submersible Pumps (ESPs), Distributed Temperature Sensing (DTS) and Distributed Acoustic Sensing (DAS)

- DTS and DAS can be replaced without pulling the tubing string or interrupting production