The Crest Packer is a weight set service packer for high-pressure remedial work such as acidizing, fracturing, and squeeze cementing.

It sets with minimal tubing manipulation and will withstand differential pressure from above or below.

When set, a balance piston is actuated as pressure increases, downward force is exerted on the inner mandrel, thus ensuring the equalizing valve is not pumped open.

A large integral fluid bypass allows the packer to be run quickly with minimal chance of swabbing off packing elements or dulling hold-down slips. Rotation is not required to retrieve the tool, and its equalizing valve opens with the first upward movement.

Standard equipment includes carbide tipped hold-down slips, lower slips, and drag blocks.

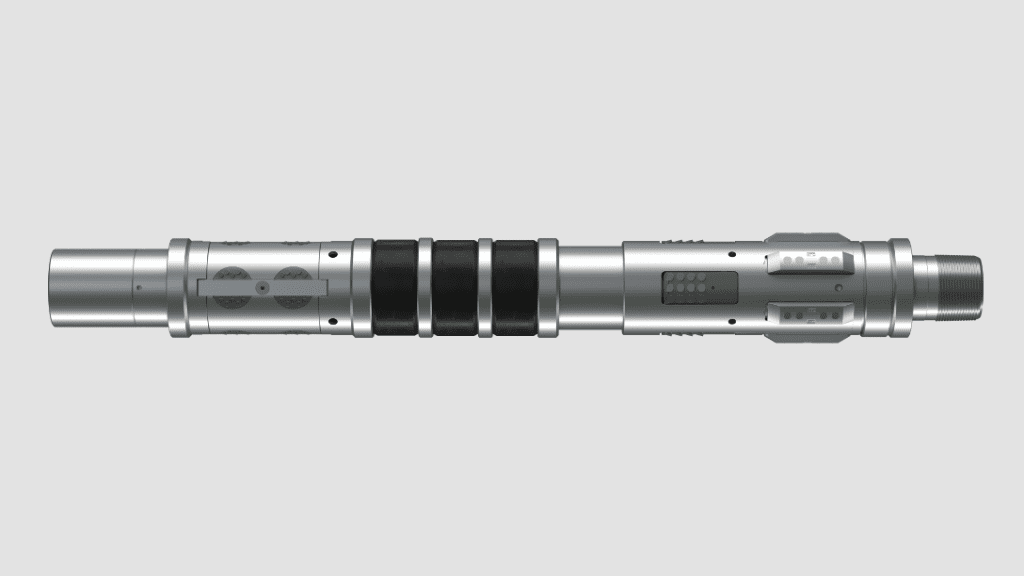

Innovex’s CPW Retrievable Squeeze Packer is designed to perform all the tasks required of a retrievable stimulation and work over packer and withstand high pressures from above or below.

It can be used in all types of squeeze cementing, fracturing, and acidizing with subsequent testing.

The hydraulically actuated hold down slips and mechanical lower slips are carbide tipped for long and dependable service. The CPW’s packing element system is the proven three-section type, but it is heavier and more reliable than packer systems with an integral bypass.

This packer runs with a separate unloader, such as the Locking Compression Unloader, eliminating the possibility of pumping open that can occur with many equalizing valves.

The Innovex PPI-CPW Perf Wash packer system is a compression set tool designed to isolate perforations or zones for washing or acidizing. The size of the zone can be adjusted to the desired length.

The PPI-CPW Perf Wash tool sets and releases with a quarter (1/4) turn. Hydraulic hold down slips allow for a straight pull to release. The automatic J-Slot allows for the packer to latch back in the run-in position.

Features

- Adjustable Spacing

- Integrated Unloader

- Rugged Carbide Slips

The Transpack Cementer is designed to provide a tension set full opening packer for remedial operations such as acidizing, fracturing, squeeze cementing, and casing testing. It can also be run above our WLTC Retrievable Bridge Plug (with a special J-slot).

This packer will remain tightly set and packed off with a high-pressure differential from either the tubing or annulus. It has fully enclosed bi-directional slips and large surface area drag blocks, both of which are fitted with durable tungsten carbide inserts.

The Scab Liner Assembly is an economical method of isolating casing leaks or existing perforations in producing and injection wells.

It can eliminate repetitive squeezing and the need to install a full liner. This assembly is mechanically set, fully retrievable in a single trip and incorporates a unique design with large bore sizes that enable standard tubing to run through the liner.