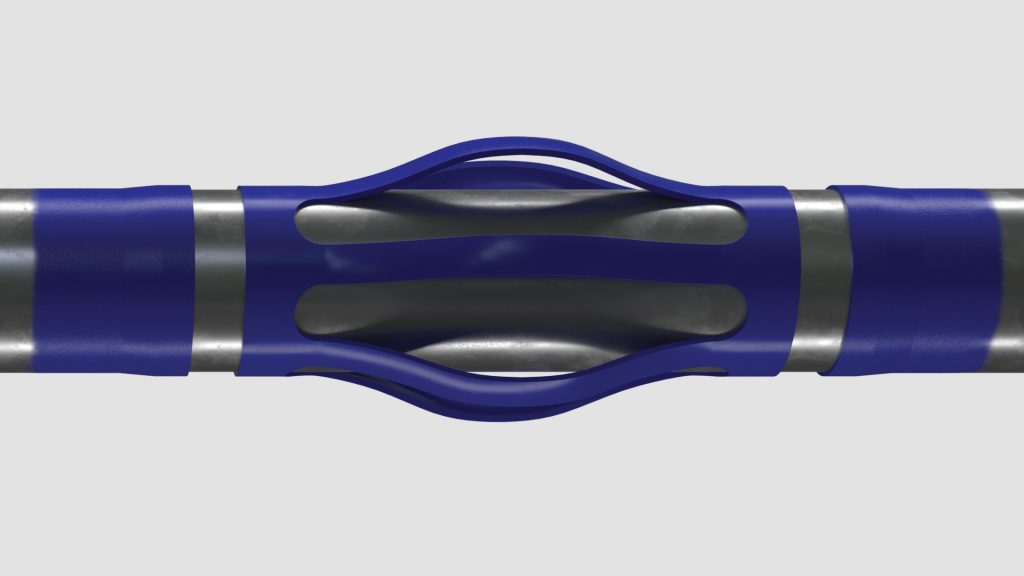

Compared with metal downhole tools, WearSox creates centralizers and stabilizers that are denser and stronger.

They also facilitate a lower coefficient of friction on the casing that increases durability and results in an economical and cost-effective solution to deliver high-production rates.

Unlike other thermal sprays that are limited to very thin formations, WearSox can be applied in deposits as thick as three inches. And by keeping the application temperature low, the integrity of the casing string is protected.

WearSox Products offer technology that is typically used in four key applications — but the possibilities for customization within those categories are virtually limitless. Matched with our skilled engineering team who can customize products for your specific application, WearSox products replace third-party metal centralizers, stabilizers and stop collars that may wear over time and lose functionality. Our patented spray can also be used for hardfacing, particularly on drill pipe, as an alternative to traditional welding. With such extensive versatility, WearSox is an oilfield solution unlike anything else.

WearSox® can be sprayed internally or externally on any centralizer on the market to create a StopSox stop device to ensure the centralizer will remain in place throughout casing running operations – even with deep water centralizers.

Thermal Spray StopSox provides 100,000 lbs. of holding capacity and can withstand shear forces in excess of 155,000 lbs. for a 7-3/4-inch collar.